It’d be difficult to find a tradie or a DIY’er who’s not familiar with the saying about the importance of having the right tool for the job. For anyone who’s ever worked with wood, it’s a humble reminder not to confuse the first blunt object you get your hands with a proper hammer … unless, of course, it is a proper hammer. Admittedly, we’ve all done it; but there’s another, almost-as-common instance where the “right tool rule” is ignored just as quickly as with the hammer. It’s countersinking screws.

And let’s be honest here too – everyone’s tried at some point to countersink a screw by either muscling it in flush, or by using a Philips head screwdriver to brutishly gouge out the top of the hole. The first method more than likely popped the screw head, and the second probably did even more damage to the working surface than you care to remember. If there’s ever going to be an ideal time to have the right tool, it’ll be when you’re countersinking.

Choose Your Bit

Whether it’s for cleaner esthetics or tighter clearances, there’ll always be a need for countersinking fasteners. That’s why when it comes to getting the job done, there’s no substitute for using properly sized and properly tipped countersink bits for wood, metal, plastic, or concrete to get perfect results every time.

From basic, high-carbon steel countersinks for backyard woodworking, to high-speed steel (HSS) carbide-tipped flat countersinks for industrial use; there are dozens of bits designed for boring and deburring countersinks that can be purchased either individually or as complete sets. The range of choices can seem overwhelming, but they each have their advantages. That’s why it’s important to remember that behind all the numbers and specs, they generally fall into four main categories.

Fluted Bits

Fluted bits are short-shanked, cone-shaped bits that have between one and five cutting edges and are manufactured in an array of chamfer angles to match the angle of incline for almost any fastener’s head. Fluted bits are used after all your pilot and clearance holes have been drilled, making them the final step in the boring process.

Cross Hole Bits

Cross hole, or Welden-style bits are a variation of fluted bits which, instead of using cutting edges to create recesses, rely on an angled core hole to essential peel away and expel residual borehole debris. Because of their flute-free design, they’re best used for softer materials and deburring recess holes.

Combination Bits

Hex-shanked combination bits consist of a full-sized straight or tapered bit, a fluted countersink, and an adjustable depth stop. Depending on how they’re designed, these bits can also accept round-shanked bits as well as free-spinning collars to prevent damaging the working surface.

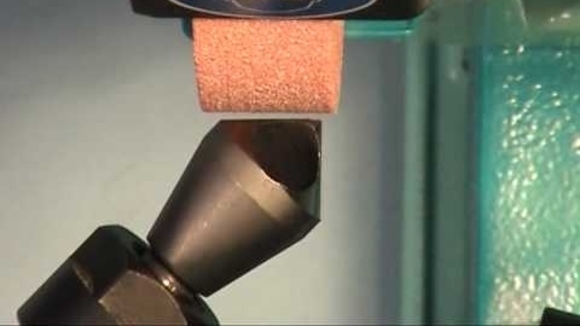

Flat Bits

Most commonly used for metalworking, flat bits are completely cylindrical shaped and feature a fixed guide that fits inside a clearance hole, and a fluted profile that performs the recess clearancing for the countersink. With no angles to accommodate, these bits are designed almost exclusively for cylindrical-, or hexagonal-headed fasteners.

Suffice it to say, regardless of whether you’re a DIY’er countersinking a tapered screw into a prized piece of antique furniture you’re restoring, or you’re responsible for purchasing countersink tooling for a tight-tolerance assembly line, you can rest assured that you can order a countersink for any need.

Countersinks and Counterbores

Despite their similarities, you also want to keep in mind that the type of bit that’s needed will always depend on the type of recess that needs to be bored. Not every recess that ends up being called a countersink is a countersink; so it’s important to understand the difference between countersinks and their very close cohorts, counterbores.

Countersinks

Countersink holes are drilled at a tapered angle, allowing the underside of the fastener’s head to basically “rest” in the recess; and are typically drilled to a depth that’ll allow the head to either sit flush with, or just slightly below the surface of the working surface.

Counterbores

Counterbore holes are drilled to a flat bottom, allowing a fastener’s head or a nut, along with a washer and the fastening tool, to fit fully inside the hole. Counterbores are typically drilled deeper than countersinks for extra-strong bonds between working materials.

The Final Word

At the end of the day, maybe the most important thing to remember is that despite their simplicity, bits are precision instruments – and it takes investing in the longest lasting and highest quality ones to yield premium results. With countersink bits in particular; there’re no bargain-buys or low-cost options – quality costs – but it also shines through in the final product.

Regardless of whether you’re recessing to achieve a few clean, moderate strength joints in wood or plastic, or you need lots of heavy-duty metal joints with tight clearances, be sure to contact a retailer that’s guaranteed to have the broadest selection of bits available. You’ll be amazed by the difference that your choice of bits can make.